The usual, boring, spoke length calculators allow only the same number of

hub holes, rim holes and number of spokes. What a waste of life and inteligence! This is a thing of the past. The times

when it was important

that a good bicycle

wheel lasts few decades without breaking a spoke are definitely gone. The new

trend is esthetics above functionality; and this requires

to be able to build a wheel with any kind of combination of holes and spokes. This is where I jump in. What you will get

here is a spoke length calculator (as well as wheel building motivator) for any

number and combination of holes, spokes, cross

patterns.

I’ll give more detail. Parts of

the wheel are hub, rim and spokes. The hub has two flanges, left and right, each having half the total number

of hub spoke holes. This also defines

the left and right side of the wheel.

The holes on the left and right flange are offset by an angle; if that wouldn’t be the case, we could not have radial

spokes on both sides of the wheel. The spoke holes in the rim, however, are

less obviously divided to left and right and it is important not to confuse

the total number

of rim holes with the number corresponding just to one side of the wheel. Further,

spokes might be inclined

out of the radial direction

for some angle -

this is usually expressed as a cross-number C, the number of spokes on one hub flange

that a certain spoke crosses. Radial spokes don’t cross any other spoke, so they have cross number C = 0. When C is not 0 we might have two kinds of spokes on the same side of the wheel:

leading spokes and trailing spokes.

The first ones are inclined clockwise, the others counter-clockwise. And finaly, you might not want to (or could

not) use all the holes in the hub or in

the rim. We will consider all of

these possibilities.

|

| Figure 1. Schematical model of a Wheel. |

Figure 1 shows a wheel schematicaly. Point O is the center

of the wheel. Line HR represents a radial spoke that goes through

hole H in the hub and hole R in the rim and has inclination angles

α = β = 0 to the x

axis. If the effective rim radius is Rr = OR, and hub-hole radius

is Rh = OH, then the length

of radial spoke would be S0 = Rr - Rh. Line AB represents non-radial spoke. It’s starting

inclination angle is α and

ending inclination is β. Note that AB

is a projection of the spoke to the plane xy.

We have to take into account that spoke has a

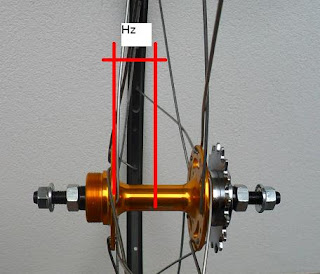

component in z direction. If Hz

is a dimension from the hub flange to the center of the rim (figure

2), then the spoke length is straightforward to calculate:

LAB 2 = (Bx − Ax)2 + (By − Ay)2 + Hz2 = R2 + R2 + Hz2 − 2RrRh cos (β − α)

|

| Figure 2. Hub with indicated dimension Hz . |

The unique

way to describe a general wheel is to assign the starting hole in the hub A and the ending hole in

the rim B to every spoke. We define

the parameters of the wheel: Hh is the number

of hub holes in one

flange of the hub, Hr the

total number of rim holes (i.e. all the holes in the rim), and S the number

of spokes in one flange of the hub. With these parameters we build

one side - left or right

- of the wheel. Number of

spokes on left and right

side of the wheel might be different; if that is the case, we use notation Sl and

Sr.

For each spoke i , (i = 1, 2, ..., S) we note two indexes: the number of the hub hole Ai and

the number of the rim hole Bi. We count hub and rim holes in a counter-clockwise direction starting at position β = α = 0 with hole number

1. Index Bi could

have zeros, negative

numbers, or numbers bigger then Hr when

C > 1. This

is OK when calculatig the spoke length,

but for the hole count it is more practical

to have only positive numbers in the range 1 to Hr; therefore we might add Hr to the zero

or negative number

and subtract Hr

form numbers greater

then Hr. Using notations ∆α = 2π/Hh and

∆β = 2π/Hr for

angle segments in the

hub and rim respectfully, we have

the equation:

Li 2= R2 + R2 + H2 − 2RrRh cos (∆β(Bi − 1) − ∆α(Ai − 1))

Li 2= R2 + R2 + H2 − 2RrRh cos (∆β(Bi − 1) − ∆α(Ai − 1))

which

defines spoke length for any spoke i and any possible wheel composition.

The key point is to define indexes Ai

and Bi.

We can define them

individually, without calculation, ”by hand”.

Automatism is, however,

much appreciated, especially in later years of your life. That is why I wrote

a program wheel that calculates indexes Ai and Bi, spoke

lengths, draws a wheel and makes a finite element model for the calculation of stresses in the wheel.

Indexes Ai and Bi are

calculated as follows.

We would prefer the spokes to be equally distributed over the hub, with constant angle segment ∆γ = 2π/S. We first find Ai =

j, i.e. a hole j in the hub which has the closest angle to the angle (i − 1)∆γ

of i-th spoke:

Ai = MINj |(i − 1)∆γ − (j − 1)∆α|, j = 1, ..., Hh

In similar manner, we

would find Bi = k:

Bi = MINk

|ϕ + (i − 1 + (−1)i+1C)∆γ − (k − 1)∆β|, k = 1, ...,

Hr

ϕ = π/Hh is the offset angle between the holes on the left and right flange of the hub. We must add this angle when calculating the right side of the wheel, but not for the left

side.

Example 1. Let’s first give a simple

example: the regular

wheel. It has Hh = S = N = Hr/2, ∆α = 2π/N ,

∆β = ∆α/2 and arbitrary cross number C. Spoke indexes are, in compact notation: Ai

= i and Bi = 2(i +(-1)i+1C) -1, and the difference in the angles is:

∆β(Bi − 1) − ∆α(Ai − 1) = (−1)i+1C∆α

With numerical data for

a 32-spoke wheel, Rr = 298 mm, Rh = 26, Hz

= 20 mm and N = 32/2 = 16, we get spoke lengths

(in mm) on one side of the wheel: 272.7, 274.9, 280.9, 289.7 and 299.8 for C = 0, 1, 2, 3, 4

respectfully. All the spokes on one

side of the wheel have the same length. The other side of the wheel could have

different spoke length, because of different

dimension Hz or different C (figure 3).

Example 2. Now, let’s

present a more complicated case. I have recently built a rear wheel for my fixie with

32-hole hub, 36-hole rim and 16 spokes

for the whole wheel, which means with parameters Hh = 16, Hr = 36, S = 8 (figure 4, left side).

Not unexpectedly however,

one spokes broke after

about 200 km and another one after

another 200 km.

I made a finite element analysis of the wheel with beam

elements. Loading was 500 N vertical gravitational force and 250 N horizontal force in the

chain acting on the edge

of the hub. The stress

analysis showed that the stress in the spokes was f =1.63 times

greater than the stress would

be in an ordinary 32-hole Wheel.

I experimented with different wheel parameters and as a first solution

I added 4 spokes to the right side of the

wheel (figure 4, right), which reduces the factor to f=1.17. The experiment is still on-going. I will ride with this wheel until possibly the

next spoke breaks, and then decide about the new wheel configuration.

|

| Figure 4. Fixie rear wheel, Hh=16, Hr=36. Left: 16 spokes. Right: 20 spokes. |

|

| Figure 5. My fixie. Both hubs have 32 holes. Front wheel: 24-hole rim and 16 radial spokes. Rear wheel: 36-hole rim and 20 spokes, mostly cross 2. |