Plastic meshes obviously become my favorite material for bicycle carriers.

After mesh handlebar bag and mesh under seat bag (see here), it's now time for

something bigger - a mesh rack. I hope it will be the revolutionary idea how to

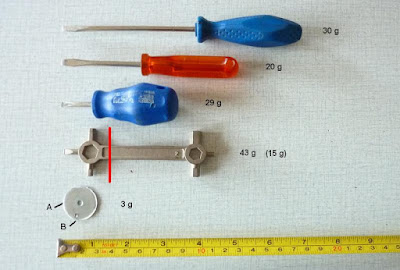

carry your bicycle stuff with minimal weight containers. This front rack is made

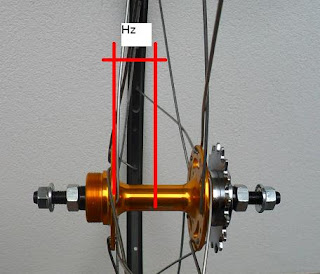

of a bit sturdier, 1 mm thick mesh. Its dimensions are 40 x 30 cm and is attached

at one end to the front tube or brake cables and at the other end to the old style

Shimano derailleur cables which run outside the handlebar tape. Weight: 15 g.

You just put the bag or small rucksack (up to 15 L) in it. maybe secured by a

piece of string. If you don't have Shimano style cables, attach any kind of cable

to the drops of the handlebar.

On the other end of the bicycle you might attach something bigger - like a tent -

under the seat and you're good for a RTW trip. I will show this set-up shortly.

|

| Simple mesh rack ... |

|

| ... with a bag in it. |

|

| ... and with a 15 litre rucksack. |